Description

Monitoring pH is crucial in producing consistent, quality yogurt. Yogurt is made by the fermentation of milk with live bacterial cultures. Most yogurt is inoculated with a starter culture consisting of Lactobacillus bulgaricus and Streptococcus thermophilus. Once the live culture is added, the mixture of milk and bacteria is incubated, allowing for fermentation of lactose to lactic acid. The pH of the mixture drops and becomes more acidic due to the lactic acid production; it is this reduction in pH causes the casein protein in milk to coagulate and precipitate, resulting in a yogurt-like texture.

Yogurt producers cease incubation once a specific pH level is reached. Most producers have a desired point between pH 4.0 and 4.6 in which fermentation is stopped by rapid cooling. Within this range of pH there is an ideal amount of lactic acid present for yogurt, giving it the characteristic tartness, aiding in thickening, and acting as a preservative against undesirable strains of bacteria.

By verifying that fermentation continues to a predetermined pH endpoint, yogurt producers can ensure their products remain consistent in terms of flavor, aroma, and texture. A deviation from the predetermined pH can lead to a reduced shelf life of yogurt or create a product that is too bitter or tart. Syneresis can also occur if fermentation is stopped too early or too late, resulting in yogurt that is respectively too alkaline or too acidic. Syneresis is the separation of liquid, in this case whey, from the milk solids. Consumers expect yogurt to remain texturally consistent, so ensuring fermentation is stopped at the appropriate pH is vital to consumer perception.

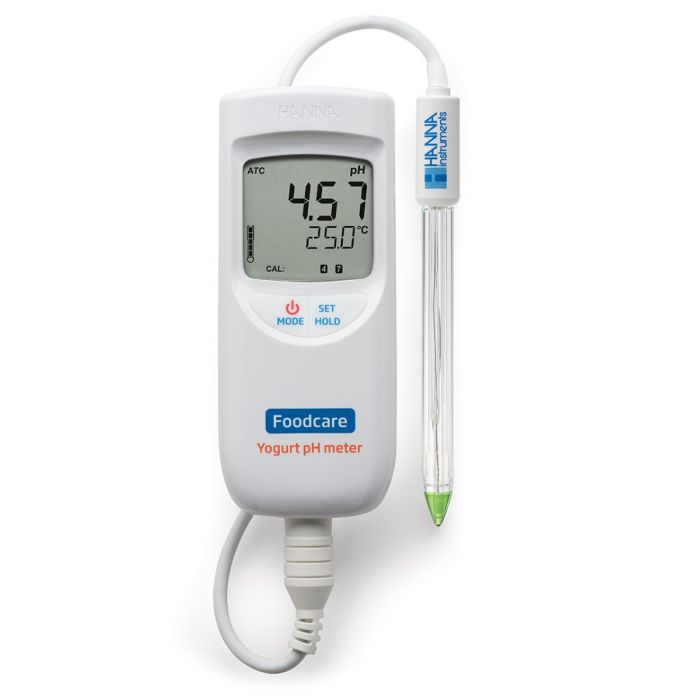

The HI99164 uses the FC2133 amplified pH electrode with glass body. This specialized electrode offers numerous features that improve pH testing for yogurt producers. An integrated temperature sensor allows for temperature compensated pH measurements without the need for a separate temperature probe. The probe’s conical sensing bulb ensures stable calibration and measurement in semi-solids and emulsions like yogurt.

An integral part of any pH electrode is the reference junction. The reference junction is a part of the electrode that allows for the flow of ions located in the reference cell into the sample being tested. It is vital that this flow occurs in order to complete an electrical circuit, which ultimately determines the pH value. Any clogging of the junction will prevent completion of the circuit, resulting in readings that are erratic or constantly drifting.

Clogging of the reference junction is a common challenge faced by yogurt producers as the milk solids and proteins can easily build up on the electrode. The open junction design of the FC2133 utilizes a viscolene reference electrolyte that comes into direct contact with the yogurt sample. Without a physical junction, the electrode resists clogging and continues to provide accurate, stable readings.

Glass Body

The glass body of the FC2133 is chemically resistant and quick to reach thermal equilibrium, allowing for a faster, more stable response when taking pH measurements in samples that are not at ambient temperature.

Conical Glass Tip

The conical shaped tip design allows for penetration into solids, semi-solids, and emulsions for the direct measurement of pH in samples such as yogurt.

Open Junction Reference

The open junction design consists of a solid gel interface (viscolene) between the sample and internal Ag/AgCl reference. This interface not only prevents silver from entering the sample, but also makes it impermeable to clogging, resulting in a fast response and stable reading.

Built-In Temperature Sensor

Errors in calibration and measurement are eliminated with the Automatic Temperature Compensation provided by the integrated temperature sensor.

Features at-a-glance

Waterproof – The HI99164 is a waterproof meter rated IP67 for immersion in up to one meter of water for 30 minutes.

Automatic Calibration – One or two-point calibration is automatic to two selectable buffer sets.

Automatic Temperature Compensation – An integrated temperature sensor allows for automatic temperature compensation of pH measurements.

Multi-Level LCD Display – The split-level LCD displays both pH and temperature readings, along with indicators for reading stability, battery percentage, and calibration instructions.

On-Screen Tutorial – Clear tutorial messages and directions are available on-screen to quickly and easily guide users through setup and calibration.

Battery Error Prevention System – The meter will automatically shut off if there isn’t enough power to obtain an accurate measurement.

Battery Life Indicator – The battery percent level is displayed at start up alerting the user to the remaining battery power that is available.

Ordering Info

HI99164 is supplied with FC2133 pH probe with internal temperature sensor, HI70004 pH 4.01 buffer sachet, HI70007 pH 7.01 buffer sachet, HI700643 electrode cleaning solution sachets (2), 100 ml beaker (1), batteries, calibration certificates for both meter and probe, instruction manual, and rugged thermoformed carrying case.