Description

HI981413 Nutrient Dosing System series is engineered for maintaining the concentration of fertilizer nutrient solution used in hydroponics and irrigation water. The nutrient concentration in the water used for irrigation is critical for the successful propagation and growth of plants. The HI981413-00 uses an amperometric conductivity sensor for measuring the amount of fertilizer in the solution. The meter can be programmed to display results as EC (electrical conductivity) or as TDS (total dissolved solids). The EC results are displayed as mS/cm while TDS is displayed as ppm with a selectable conversion factor from 0.45 to 0.99. The HI981413 was developed to be an inexpensive solution for the horticulturist to maintain the ideal fertilizer concentrations. Simply insert the probe and injection valve in-line with the re-circulation pump and provide the chemical to be dosed.

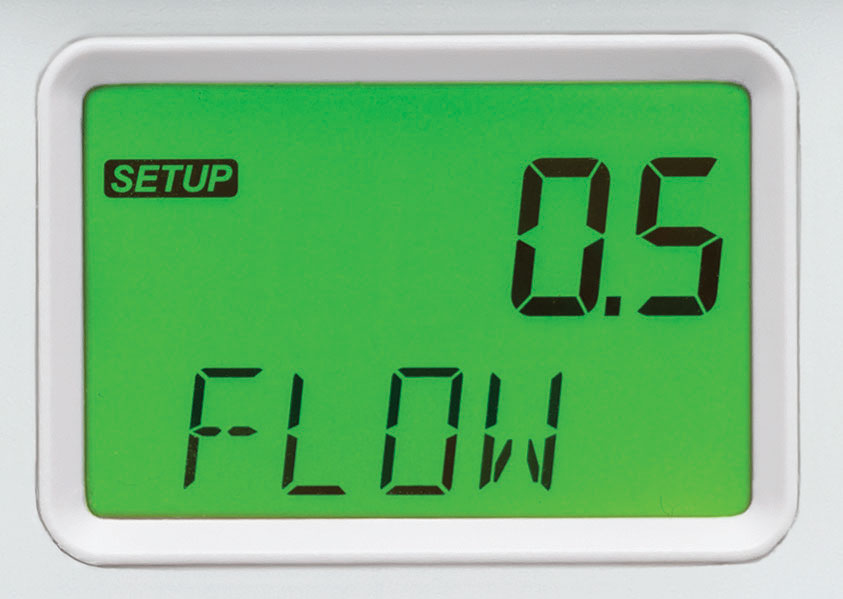

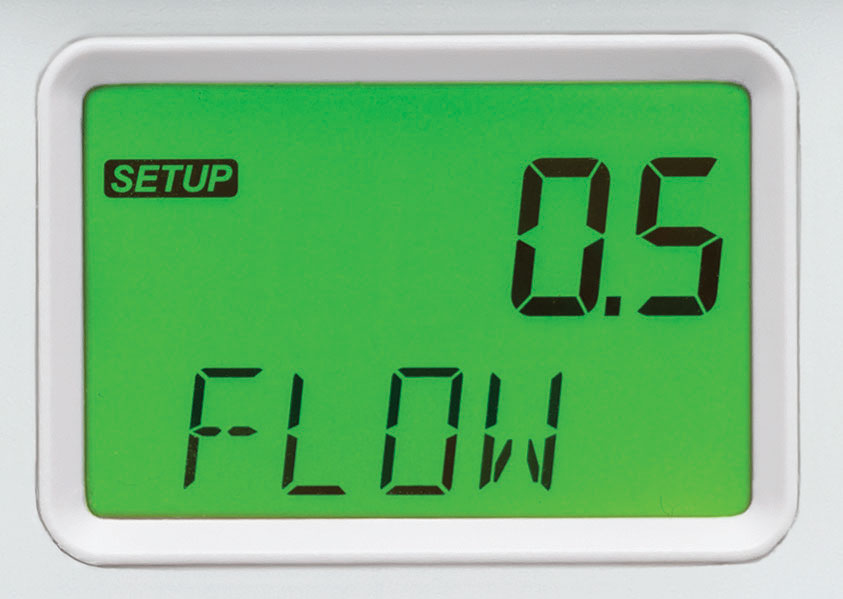

Multi-color LCD

The HI981413 series features a multi-colored LCD that provides for a quick way to see the status of the pool controller. If in control mode and operating as intended the display will be green. If control is not enabled then the display will be yellow while in an alarm state the display flashes red.

Intuitive LCD

Both conductivity or TDS and temperature are displayed with status icons that show when the pump is dosing and the control mode status.

Programmable Alarm System

Hanna controllers allow users to enable or disable the low and high-level alarms for EC/TDS. When an alarm is activated, all dosing will stop. For added safety, the alarm system also offers overdosing protection in that if the set point value is not corrected within a programmed time interval then the meter will go into alarm status.

On-Screen Features

Adjustable Flow Rate

The flow rate from the dosing pumps is adjustable from 0.5 to 3.5L/h. Larger bodies of water require more chemical to be dosed than smaller ones in per unit of time. The adjustable flow rate, like the proportional band, allows for better control in maintaining a desired set point .

Automatic Proportional Pump Control

The peristaltic dosing pump can be controlled by simple on/off or more advanced proportional control which helps prevents overshooting of the set point. When using proportional control the flow rate that is programmed, will be impacted by the proportional band used. The closer the reading is to the set point the longer it takes for the peristaltic pump to complete one revolution. If the reading is outside the proportional band then the amount of time it takes to complete one revolution is based on the flow rate programmed.

Acid Tank Level/Flow Switch Input

The BL100 allows for a connection to an optional level controller or flow switch. This input can be used to disable the dosing pump when there is no chemical left in the reservoir tank or there is no flow due to the pump being turned off.

Built-in Dosing Pump

Peristaltic Dosing Pump

The HI981413 series features a peristaltic dosing pump that is superior to diaphragm versions due to the ability to self-prime when there is no liquid in the uptake line.

Brushless Motor

The brushless motor does not have nay gears or brushes that can wear out. A brushless design provides for a long life and little maintenance. The compact stepper motor allows for very precision control over the dosing of the chemical.

Long-life Peristaltic Tubing

The industrial grade peristaltic tubing is chemical resistant and provides for a relatively long-life. As tubing stretches over time it can be easily replaced. No special tools required.

HI30003 Amperometric Conductivity/Temperature Probe

The HI981413-00 uses the HI30003 probe that incorporates both conductivity and temperature sensors and connects to the controller with a single waterproof Quick Connect DIN connector.

Ordering Info

HI981413-00 is supplied with controller/pump assembly, HI30033 EC/TDS/temperature probe, HI7031-012 conductivity calibration solution (1413 µS/cm – 120 ml), plastic beaker, power connection cable, instruction manual and quality certificates for instrument and probe.