Description

Description:

HI520 is an advanced process controller that can be configured for applications requiring monitoring and/or control of four main water-analysis parameters: pH, ORP, Conductivity, and Dissolved Oxygen. This controller features a digital probe input(s) that automatically detects and updates the controller with the parameter that it measures.

HI520 is Hanna’s first dual-input process controller that accepts virtually any combination of compatible probes. Designed to adapt to unique process control requirements, users have the option to enable or disable each channel independently.

Additionally, HI520 introduces enhanced industrial control by operating a control-loop system whereby users have the option to run channel control either independently or configure to be triggered sequentially upon reaching the other channel’s set point(s) (1, 2, or both). The device operates a logical channel with built-in mathematical functions. This function is intended for when the controller works as an analyzer for monitoring high/low parameter levels between two identical inputs with identical measuring configurations.

Control Modes

Set points for control operations can be configured to be on/off, proportional, or PID types of control. The flexibility in programming allows for fine-tuning of a set point to be maintained with tight control preventing any overshoot and waste of chemicals.

Hold Function

Hold can also be triggered manually and by using and external digital input for disabling control mode when performing maintenance.

Configurable Alarm System

Configurable for set points and temperature or activated by abnormal operation, a red Alarm LED will blink and can easily be seen from a distance. All relays configured for control are inactivated until the alarm state is resolved.

Auto-cleaning cycle

The cleaning function allows the ability to program one or more wash cycles and use the relays to activate valves, pumps or compressed air based on the type of washing that is required to maintain probes for reliable results.

Relays

Available with up to five control and one alarm electromechanical relays.

Analog Outputs

Up to four galvanically isolated analog outputs for control of pumps and valves.

Digital RS485 Output

Can daisy-chain up to 32 devices to a remote monitoring system.

Digital Inputs

Two digital inputs available for modes including disabling, cleaning and placing the controller into hold status.

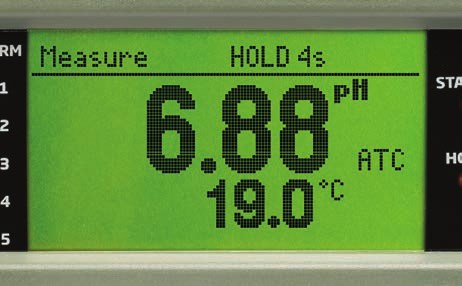

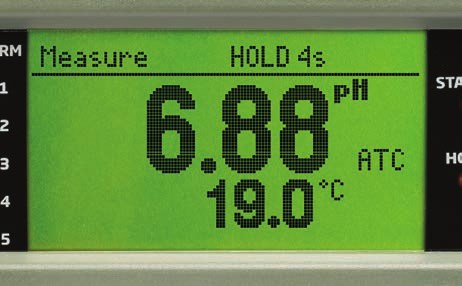

Large LCD

The LCD displays measurement information along with indicators of potential problems. The DIAG key then provides details of the issue.

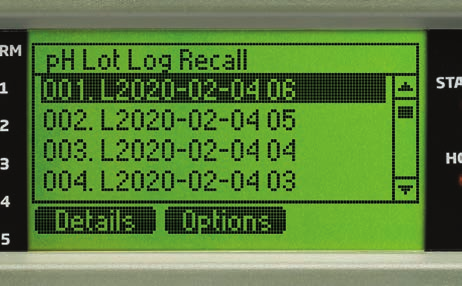

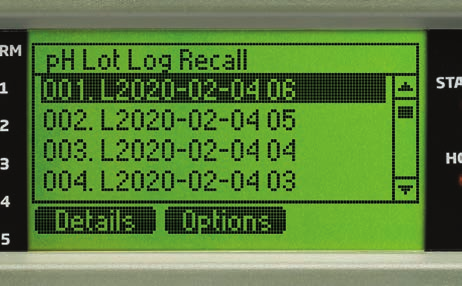

Data-logging

Store info at selectable intervals along with relay control settings and calibrations data. Up to 100 lots, each holding 8600 records. Transfer to a flash drive as a .csv file using the USB Type-C port.

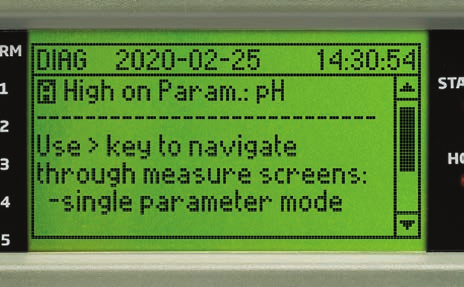

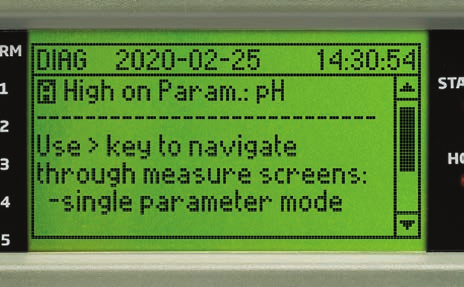

Help Button

Using the help and diagnostic button (? DIAG) will provide information related to errors or in setup mode, information about settings.