Hanna Instruments Canada

The Hanna Advantage:

A Worldwide Leader

in Technology

and Innovation

100% Quality

360 Value

Contact Hanna: (800) 842-6629

Hanna Instruments Canada

Customer Support: (800) 842-6629

End of Content.

- Products

- Parameters

- Acidity

- Alkalinity

- Aluminum

- Ammonia

- Ammonium

- Boron

- Bromide

- Bromine

- Cadmium

- Calcium

- Carbon Dioxide

- Chloride

- Chlorine

- Chlorine Dioxide

- Chromium

- COD

- Color

- Copper

- Cyanide

- Cyanuric

- Dissolved Oxygen

- Fluoride

- Formaldehyde

- Glycol

- Hardness

- Hydrazine

- Hydrogen Peroxide

- Hypochlorite

- Iodide

- Iodine

- Iron

- Lead

- Lux

- Magnesium

- Manganese

- Molybdenum

- Nickel

- Nitrate

- Nitrite

- Nitrogen

- ORP

- Oxygen

- Ozone

- Peroxide Value

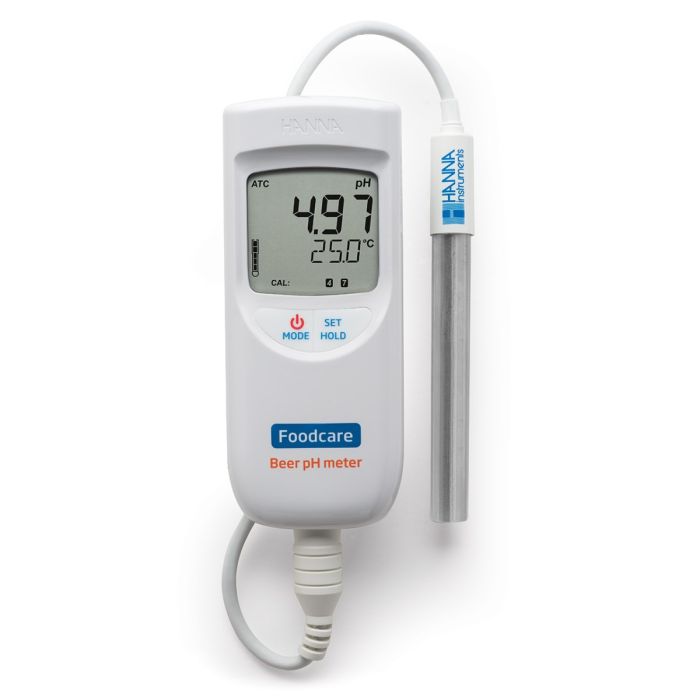

- pH

- Phosphate

- Phosphorus

- Potassium

- Reducing Sugars

- Refractometry

- Relative Humidity

- Resistivity

- Salinity

- Silica

- Silver

- Sodium

- Sulfate

- Sulfide

- Sulfur Dioxide

- Surfactants

- Tartaric Acid

- TDS

- Temperature

- Titration

- Turbidity

- Zinc

- Support